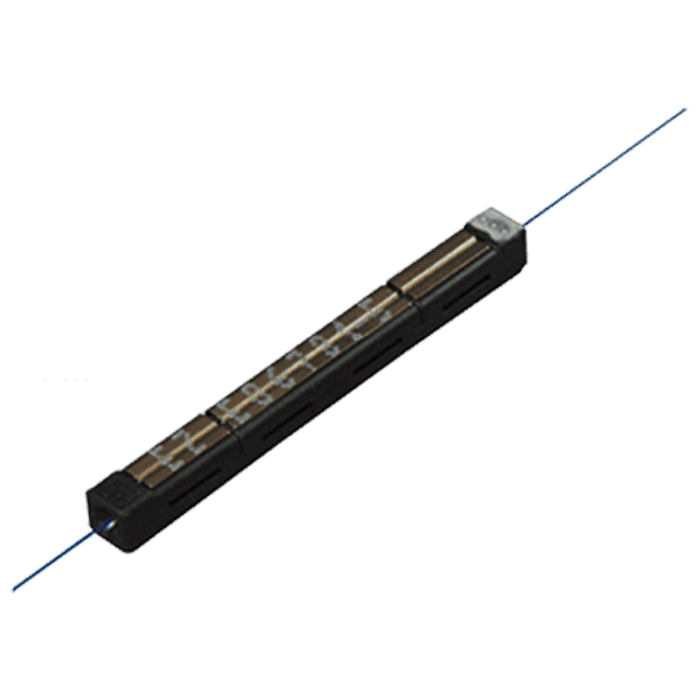

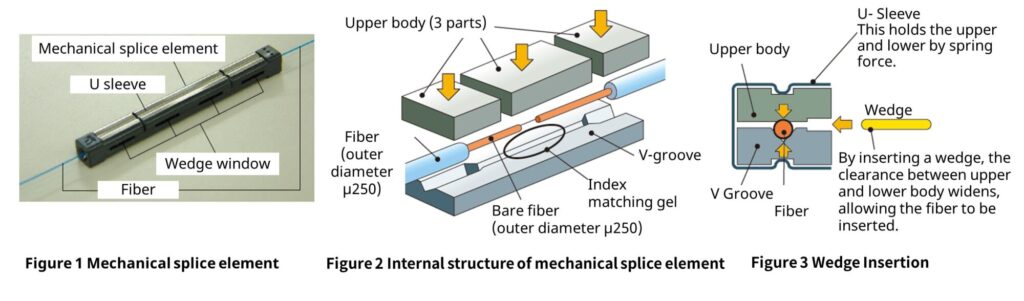

Mechanical Splice

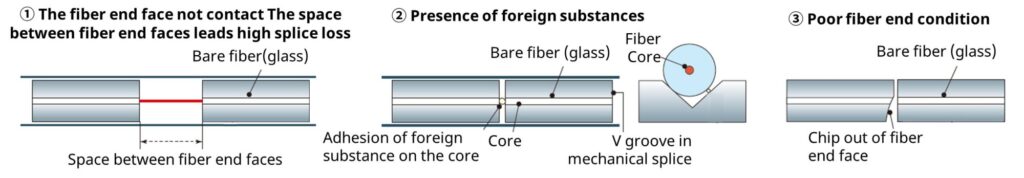

Fujikura offers mechanical splice for efficient and reliable fiber optic connections. These elements provide low loss and high return loss, ensuring optimal performance. They are compatible with various fiber types. Quality tested for reliability and durability.